The first phase of aluminum alloy online hydrogen testing and offline slag testing basic knowledge and on-site operation training courses successfully ended

The first phase of aluminum alloy online hydrogen testing and offline slag testing basic knowledge and on-site operation training courses successfully ended

Recently, by the cooperation of Metal-new and Chongqing National Innovation Institute, Chairman Ke Dongjie presided over the first phase of aluminum alloy online hydrogen testing and offline slag testing basic knowledge and on-site operation training course successfully ended in Chongqing.

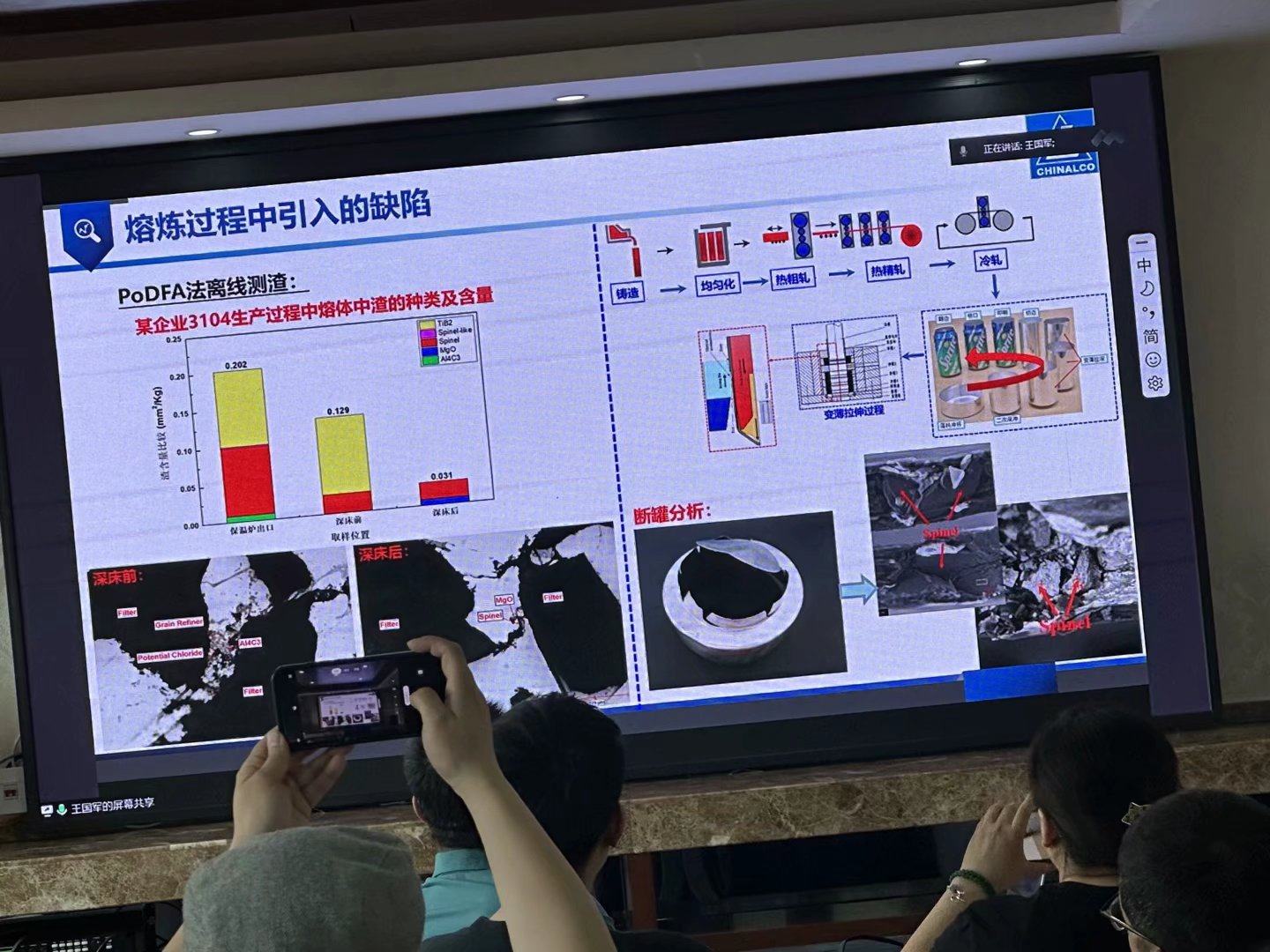

As we all know, the melting and casting process is the starting point of the "life" of metal materials, and strict control of the hydrogen content and impurity content of the material is a particularly important technical indicator for the production and preparation of aluminum alloy materials. Therefore, the establishment of strict online hydrogen and slag measurement, real-time scientific digital control, and the elimination of inappropriate hydrogen and slag content of aluminum alloy production and casting is an important means to improve the material utilization rate and the yield of post-processing, and achieve material optimization.

In view of the current aluminum alloy melting and casting level and the improvement of the requirements for casting ingot, Metxin cooperated with Chongqing Guochuang Institute to carry out the first phase of aluminum alloy online hydrogen testing and offline slag testing basic knowledge and on-site operation training courses in Chongqing for the whole country.

This paper introduces the basic situation of hydrogen measuring instrument and slag measuring instrument at home and abroad, and field practical operation training

▲The class teaches the operation steps of hydrogen measuring instrument and slag measuring instrument

▲The operation method of hydrogen measuring instrument and slag measuring instrument was demonstrated on site

Guide how to analyze from the hydrogen and slag test results and tissue analysis report for guiding production. Clarify the relevance and heritability of various data sources and materials, and share classroom examples.

▲The students are listening carefully

▲Lecturers and students took group photos

Carry out real-time evaluation of melt purification effect, and replace the current manual experience value with scientific data, which can not only better control the production of aluminum alloy materials from the technical level, but also more efficiently control product performance, reduce cost and increase efficiency, and promote the overall level of China's aluminum processing industry.

This training is only a beginning, in line with the promotion of advanced technology, to drive the development of the industry, the future of our company will also hold the second phase, the third phase of aluminum alloy online hydrogen testing and offline slag testing basic knowledge and on-site operation training, focusing on solving the difficulties of online hydrogen testing and offline slag testing. All enterprise engineering and technical personnel and corresponding material analysts who have a melting and casting workshop can sign up. Look forward to discussing with you.

Wuhushan Industry Area, Qingkou Investment Zone, Fuzhou, Fujian, China

Follow us

Website

MESSAGE

扫描关注我们