MTX CFF

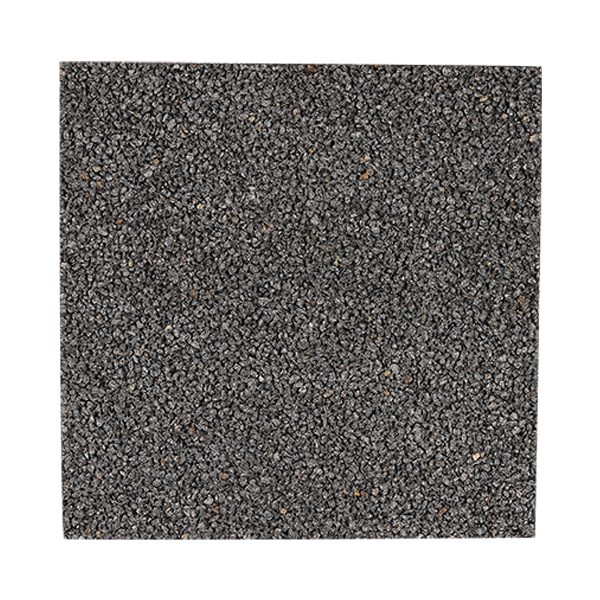

MTX Ceramic Foam Filter is the last process technology of aluminum melt purification treatment, and it is particularly important to select the second generation of foam ceramic filter plate. According to the environment of each foundry, the best filter plate is selected to filter the aluminum melt with high cleanliness.

The second generation foam ceramic filter plate produced by Metnew has the following advantages:

1. High strength, no slag (ceramide)

2. Three-dimensional network, better than honeycomb foam type

3. High opening rate, small filtration resistance, small normal static difference

4. High surface energy, strong heterophase adsorption

5. Excellent thermal shock resistance

Foam ceramic filter plate (common specifications)

|

Gauge lattice |

Aluminum liquid flow range |

Filtration capacity |

Aperture |

Selective reference | ||

|

178×178×50(7) |

25-50 |

3 |

|

1, casting selection of 10-25ppi 2, semi-continuous casting selection of 30-60ppi, high-quality aluminum profile or plate selection of 50 or 60ppi 3, continuous casting and rolling selection 50-60ppi ★ Other specifications can be customized according to user requirements |

||

|

254×254×50(10) |

45-100 |

7 |

||||

|

305×305×50(12) |

90-170 |

15 |

||||

|

381×381×50(15) |

147-280 |

20 |

||||

|

432×432×50(17) |

193-367 |

25 |

||||

|

508×508×50(20) |

274-521 |

30 |

||||

|

584×584×50(23) |

369-700 |

35 |

|

|

The second generation of foam ceramic filter plate (three-dimensional skeleton) | The first generation of foam ceramic filter plate |

| Wood quality Square face |

X 'PERT Pro MPD diffractometer analysis Main crystal phase α-Al2O3, multiform mullite, no quartz glass phase. |

X 'PERT Pro MPD diffractometer analysis The main crystalline phase α-Al2O3, cordierite or mullite or spinel phase, and quartz glass phase. |

| Mesh construction |

The skeleton support body has micro-cracks and micro-pinholes, strong thermal shock resistance, and does not drop ceramic particles. The micro-defects are conducive to the secondary deposition of fluoride and increase the adsorption capacity of heterophase in liquid aluminum. | Three-dimensional network uneven skeletal structure, especially reflected in the transverse section, blind holes, honeycomb shape. The skeleton support is smooth or there are many broken branches cracks, and the vibration is easy to drop the ceramic particles, which are all intercepted by mechanical collision. |

| Occurrence | Compressive strength > 4.5MPa, bending resistance 1.5MPa, thermal shock resistance (750℃ room temperature) > 5, does not drop ceramic particles, strong affinity for impurities in aluminum, high impurity removal efficiency, showing a large change in static pressure difference. | Compressive strength < 4MPa, generally 1.0-1.5MPa thermal shock resistance < 5, easy to drop ceramic slag, impurity removal efficiency is relatively low, showing little change in static pressure difference. |

| External view | Pink or white Beat, do not drop the clay. |

White or off-white Slapping, dropping clay, even vibrating more and more. |

| Errata | Adsorption filtration has a high impurity removal rate, and sometimes too much impurity causes a surge in static pressure difference, resulting in insufficient flow supply and "plugging". | Due to the many blind holes in the central cross section, the effective filtration volume decreases, causing insufficient flow supply and even blockage. |

Filtration and purification mechanism of foam ceramic materials

1. Through screening habitus collision interception and diffusion interception, friction, settlement and other mechanical filtration, its filtration efficiency is proportional to the mesh aperture of foam ceramics, the smaller the mesh, the stronger the interception ability of small particles;

2. The sediment layer or filter cake layer effect, with the particle deposition in the melt and the zigzag interconnecting and uneven grid wall support, the trapping ability of heterophase particles is improved;

3. The rough surface formed by the gap on the surface of the skeleton body increases the interfacial energy between the aluminum flow and the ceramic solid surface, and promotes the particle flow in the aluminum flow to be more disordered, which is conducive to the trapping and deposition of solid particles;

4. Due to the microscopic cracks and pinholes on the surface of the skeleton body, fluoride with strong affinity for particles such as Al2O3 is pre-deposited, which promotes the complete filter cake effect and strong chemisorbed force, and the ability to trap and retain the heterophase particles is stronger.

Moreover, the temperature field effect from the melting process and transmission process of the metal melt structure will inevitably form the concentration difference of the alloy solute, and the metal melt is redistribution-integration-redistribution-integration, which is also a good alloying process. Some high-melting metal phases and compounds reaggregate and grow, and fine heterophase aggregation and growth are beneficial to filtration and capture, which can also be explained from the changes in the concentration of H, Al2O3, Fe phase and Ti phase before and after filtration, especially two-stage filtration or pore gradient thick plate filtration is more obvious.

Metal-new foam ceramic filter plate is a Sino-Russian cooperation, jointly developed by Metxin and Russian academician Professor Yuri. Using liquid nano preparation technology to achieve low temperature sintering, it is a special functional material with energy saving and emission reduction and low consumption. The material has the advantages of high surface energy, high strength and long life. Nanoscale materials coated on mesh dendrites can greatly improve the filtration efficiency and sound absorption and noise reduction effect of materials, and can be used as clean products for high-end aluminum production applications, that is, high temperature liquid metal filtration materials, featuring:

(1) Three-dimensional network structure, mesh diameter less than 0.5 mm;

(2) No light spot is detected, and the number of blind holes is not more than 5;

(3) Compressive strength 2.5Mpa;

(4) Can withstand 1000-1200 degrees of temperature heating, do not drop ceramic, do not crack.

Related Products

Wuhushan Industry Area, Qingkou Investment Zone, Fuzhou, Fujian, China

Follow us

Website

MESSAGE

扫描关注我们