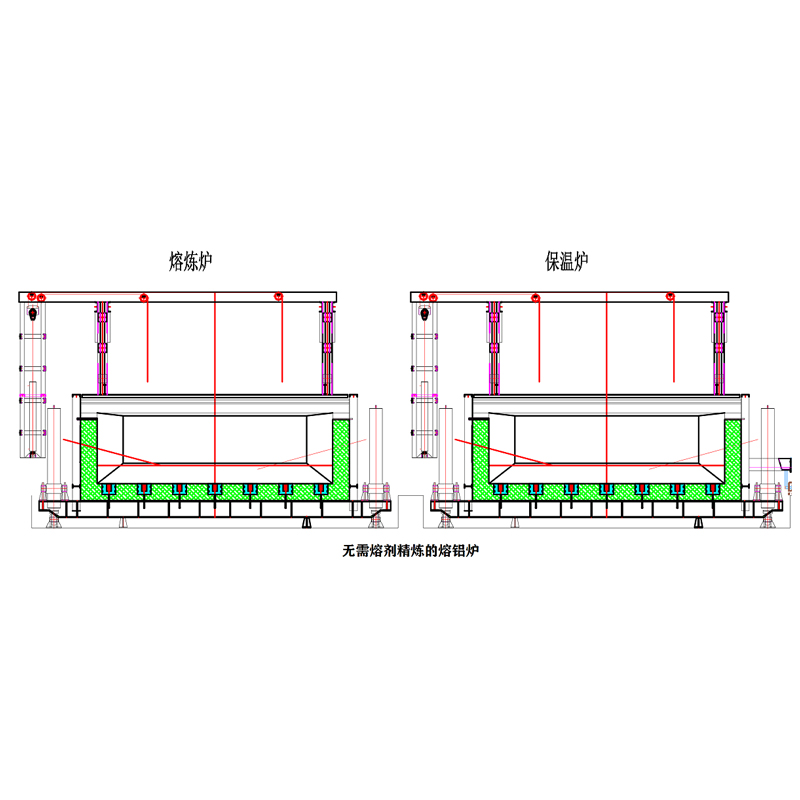

Aluminum smelting furnace without flux refining

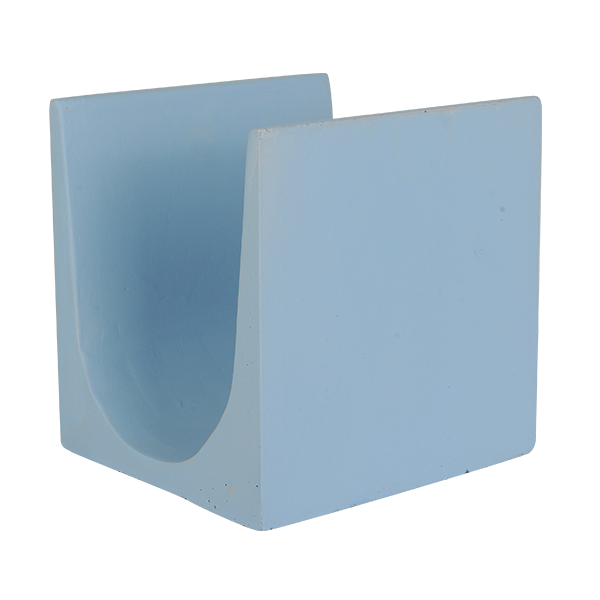

Argon gas bubble bed refining is a new technology of aluminum alloy refining without chemical flux, which was developed by Fujian Mette New Institute. In the current aluminum alloy refining process, chlorine and fluorine pollution gases are discharged, and the solid waste containing fluorine and chlorine has been classified as hazardous waste by the Ministry of Environmental Protection of China. To this end, a bubble bed refining technology is invented. Microporous refractory components are regularly distributed at the bottom of the furnace, and the pressure and flow rate of argon are intelligently controlled, so that the highly pure argon flows through these microporous refractory components to form a dispersed small bubble bed, so that the metal has been in the flotation refining of tiny inert gas bubbles from melting to the end of casting. To solve the common technical problems caused by environmental pollution caused by refining for a hundred years, the innovation can increase the efficiency of aluminum smelting processing by 30% and reduce energy consumption by 30%. There are obvious advantages in environmental protection and energy saving.

Related Products

Wuhushan Industry Area, Qingkou Investment Zone, Fuzhou, Fujian, China

Follow us

Website

MESSAGE

扫描关注我们