Fujian Metal-New Aluminum Technology Co., Ltd.

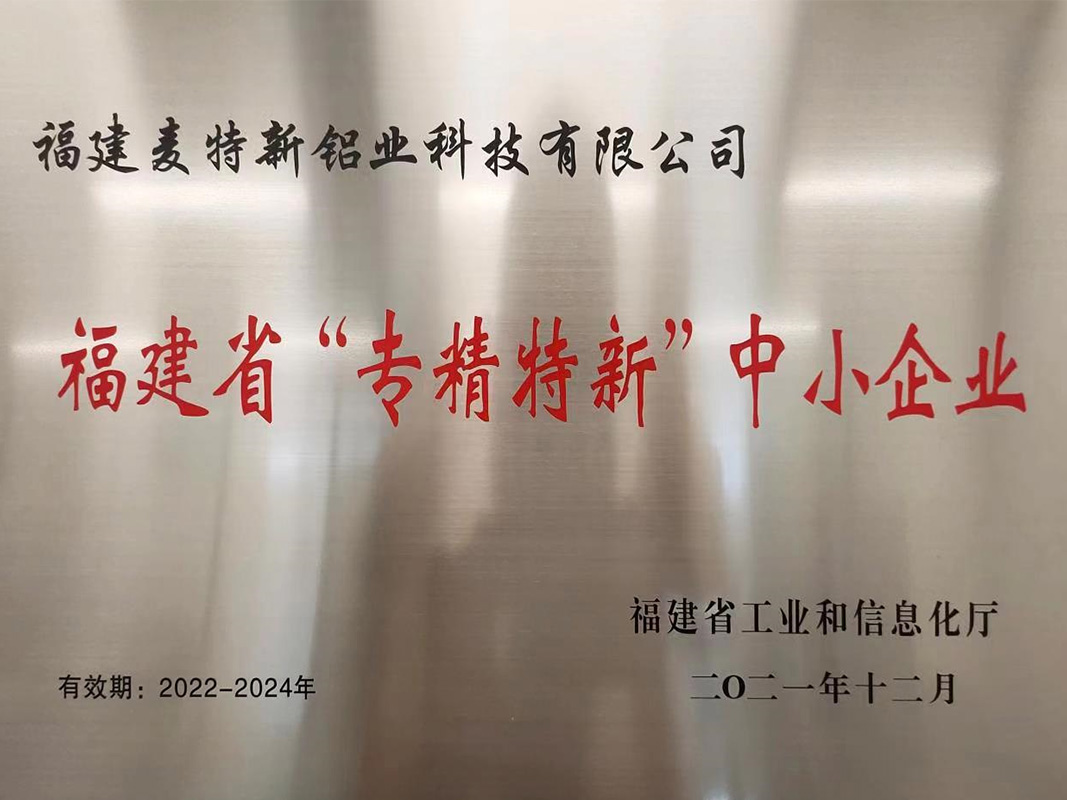

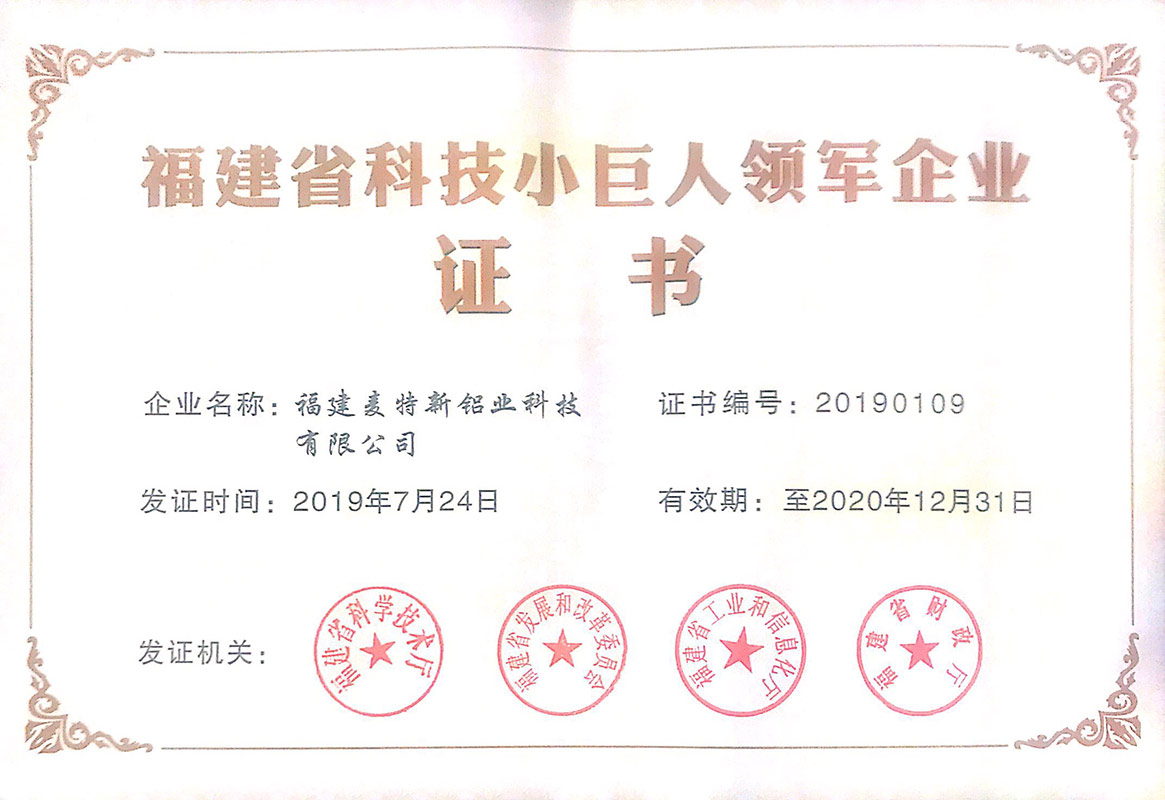

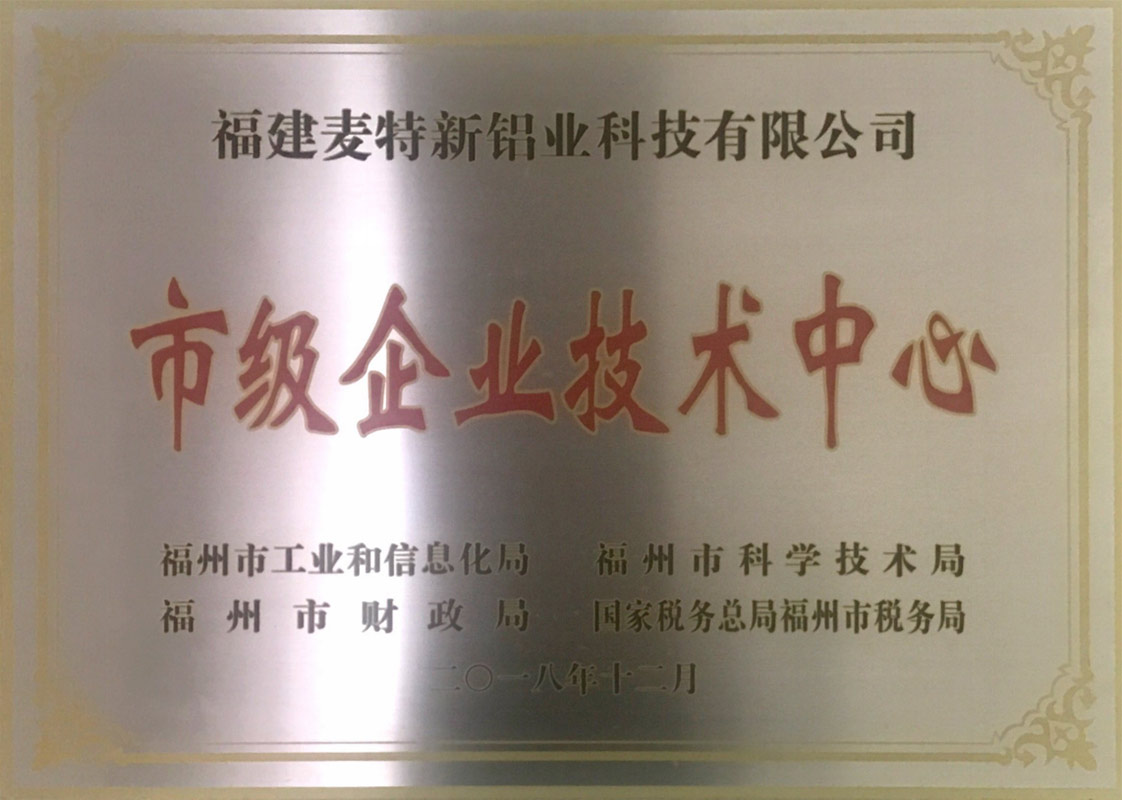

FMT is an innovative enterprise specialized in the technology and special equipments of aluminum alloy smelting process and production and research of aluminum alloy materials for special purposes with high performance. It has won honorary titles such as National High-tech Enterprises, Enterprise Technology Center in Fujian Province, “Specialized, Refined, Differential, and Innovational Small-and-medium-sized Enterprises in Fujian Province”, and Small Giant Enterprises of Science and Technology in Fujian Province. It has also established a National Institute Workstation together with the Nonferrous Metals Society of China and served as the workstation of the Fuzhou Work Base in the “Haizhi Program” of the China Association for Science and Technology. The founder of the company is the former president of the Nonferrous Metal Smelting Research Institute of Fuzhou University and Xinzuo Material and Equipment Technology Research Institute. It has been engaged in research on the treatment and purification of aluminum alloy melts for more than 30 years.

Annual sales revenue

Patented

Having a green factory

Dedicated to high-performance special applications

Manufacturer of aluminum alloy materials

The company currently has a 60-ton DC production line for melting and casting of aluminum alloy, a 15-ton DC line of special aluminum alloy, a 15-ton aluminum alloy homogenizing furnace, a 1,500-ton double-acting reverse intelligent extrusion production line with variable cross section, two high-precision production lines of fine wire drawing and straightening of seamless pipes, two sets of aluminum alloy semi-automatic die-casting machines, a 160-meter nano porous foamed ceramic production line and machining plant for special equipments for welding and processing of intelligent aluminum alloy, and a well-equipped test center building with various testing, analysis, and R&D equipments in it, including spectrometers, high-power microscope, imported hydrogen gauge and slag detector of aluminum alloy, and experimental testing instruments for the analysis and research of various material properties.

Unity and cooperation, the pursuit of excellence, being people-oriented, and innovation and honesty are the consistent beliefs of FMT.

Enterprise culture As a high-tech enterprise, FMT has a complete set of survival philosophy since its founding. FMT is like a “university”. In this “university”, FMT people are ambitious and have the courage to innovate. In just a few years, it developed fast like a rising red sun and emitted stronger and stronger light and heat.With scientific research and technological innovation as its core value, the company maintains the sustainable development of the enterprise, has an optimized organizational structure and perfect management system, and continuously increases investment in R&D and human resources. Unity and cooperation, the pursuit of excellence, being people-oriented, and innovation and honesty are the consistent beliefs of FMT. Based on the international market and market demands, the company continuously innovates technologies and develops products, takes “green metallurgy, energy conservation, and emission reduction” as the technical development direction, and provides environment-friendly and high-quality new products with low energy consumption to the aluminum industry.

Ke Dongjie, the fifth batch of national "Ten Thousand Talents Plan" talents in 2020, high-level A-type talents of Fujian Province, chief senior engineers, experts from the national scientific expert pool, experts from the think tank of Fuzhou Municipal Party Committee and Government, and the seventh special training camp for national scientific and technological innovation CEOs;

At the same time, he served as the vice chairman of China Nonferrous Metal Industry Intelligent Manufacturing Alliance, the director of Haizhi Plan of China Association for Science and Technology, the executive director of China Light Alloy Association, the director of China Nonferrous Metal Processing Association, the director of Fuzhou Advanced Aluminum Alloy Production Technology Innovation Center, the deputy director of Science and Technology Committee of Fujian Association of Foreign Universities, and the chairman of China Soueast City Industry Alliance;

He is currently an external professor of Northeastern University and Fuzhou University, a master's supervisor of Fujian University of Technology, an entrepreneurial supervisor of Xiamen University, and a research scholar of Nizhny Novgorod State University (Russia); Editorial board member of Light Alloy Processing Technology, expert of Light Metal Age magazine in China, member of the 11th Standing Committee of Minhou County CPPCC.

1985

Graduated from the Department of Nonferrous Metals Metallurgy, Northeast University, majoring in physical chemistry of metallurgical process, and served as the deputy general manager and chief engineer of Fuzhou Ronggang Aluminum Co., Ltd. under Fuzhou Municipal Bureau of Mechanical Metallurgy;

1999

Served as an external professor and supervisor for master's students in materials science at Northeastern University;

2001

Served as part-time professor and associate tutor of master students in material forming specialty of Fuzhou University; Deputy Director, Institute of Nonferrous Materials, Fuzhou University;

2002

Established Fuzhou Metal-New High Temperature Materials Co., Ltd. and served as the chairman;

2007

Served as the executive director of the China Light Alloy Association;

2010

Established Fujian Metal-New Aluminum Technology Co., Ltd. and served as the chairman, and also served as the director of the China Nonferrous Metal Processing Association;

2022

Served as the Deputy Chief Engineer of Chongqing Guochuang Light Alloy Research Institute Co., Ltd.

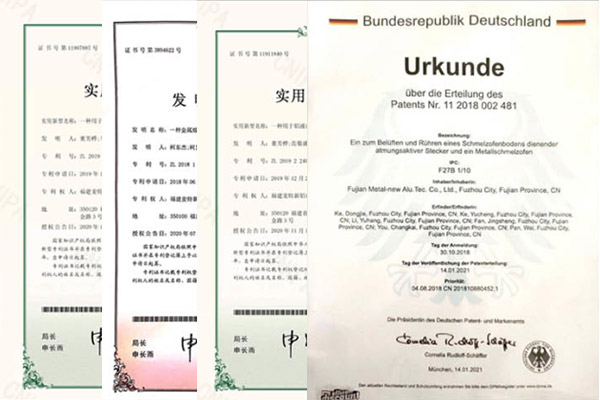

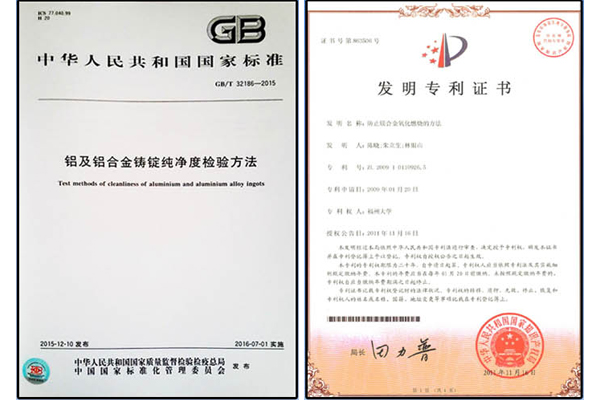

So far, he has published dozens of special reviews and academic papers, and has over 20 patents and copyrights. Served as the editorial board member of the national secondary publication "Light Alloy Processing Technology" ISSN 1007-7235. And the editor in chief has formulated three national standards: "Aluminum Intermediate Alloy", "Method for Indicating Wrought Aluminum and Aluminum Alloy Grades", "Inspection Method for Purity of Aluminum and Aluminum Alloy Ingots", as well as three industry standards: "Aluminum Melt Online Continuous Degassing Device", "Aluminum Alloy Online Degassing and Purification Process Specification", and "Aluminum and Aluminum Alloy Composition Additives".

He has successively authored two monographs: "Theory and Technology of Aluminum Alloy Melting" published and distributed by Northeast University Press as a textbook for graduate professional courses; Contemporary Aluminum Melt Treatment Technology "is publicly published and distributed by China Metallurgical Industry Press, becoming the first monograph on aluminum melt treatment technology in the non-ferrous metal industry since its 60th anniversary. It is beneficial for promoting the green metallurgical energy-saving and emission reduction process in the aluminum industry, and is expected to solve the common technical problems of pollution sources in the aluminum alloy melting process that have existed for a long time, promote technological progress in the aluminum industry, and develop high-end aluminum materials with high added value.

Wuhushan Industry Area, Qingkou Investment Zone, Fuzhou, Fujian, China

Follow us

Website

MESSAGE

扫描关注我们

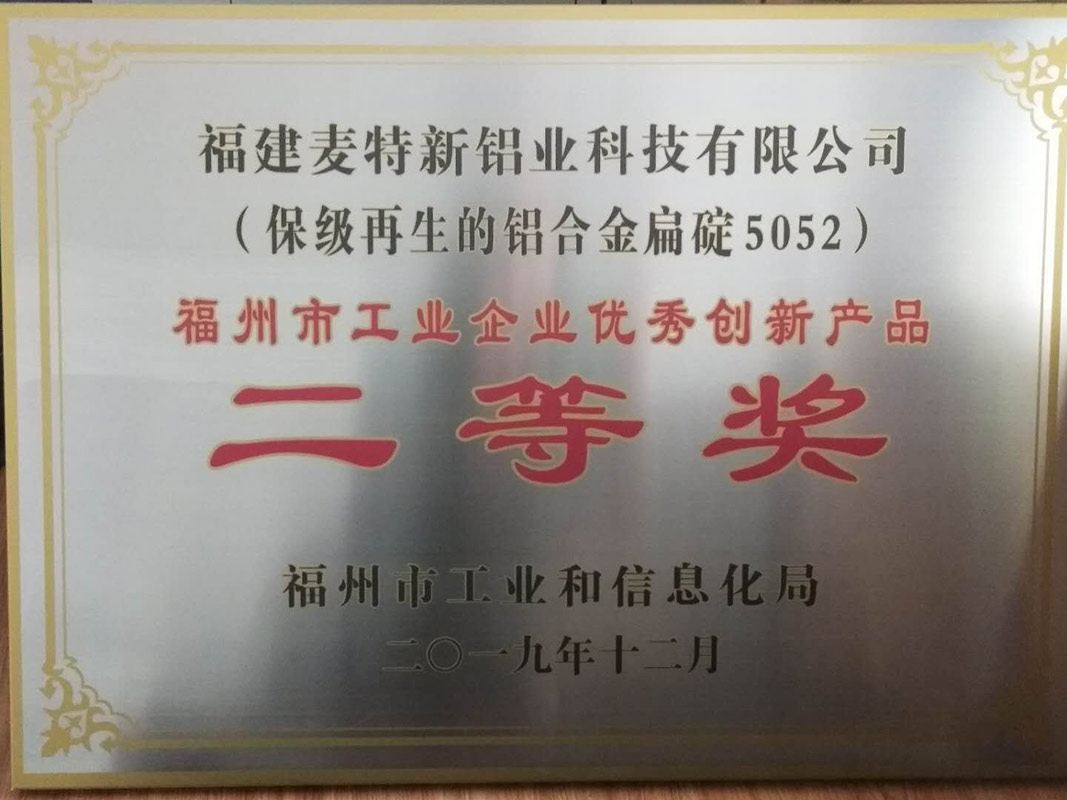

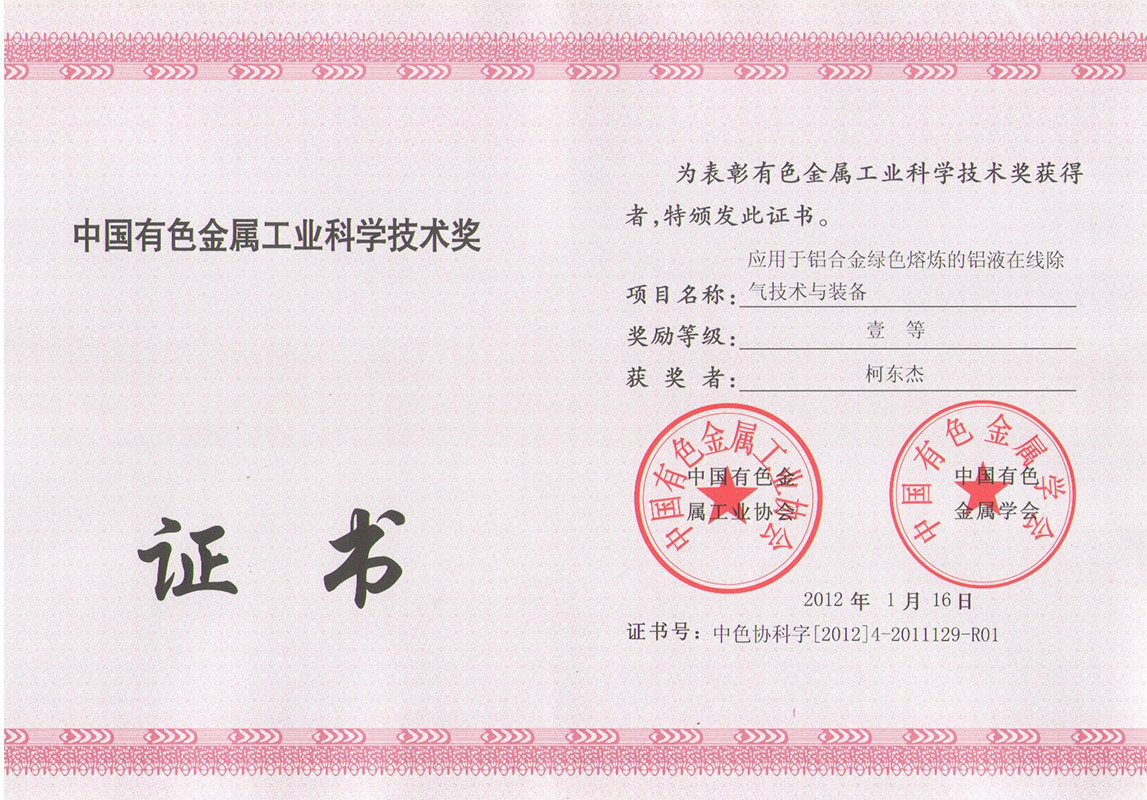

Honors previously obtained:

The fifth batch of national "Ten Thousand Talents Plan" technology entrepreneurship leading talents in 2020

2021 Fujian Province A-Class High Level Talents

First Prize of the 2012 China Nonferrous Metals Industry Science and Technology Progress Award

First Prize of the 2019 China Nonferrous Metals Industry Science and Technology Award

Second Prize of the 2018 China Nonferrous Metals Industry Science and Technology Award

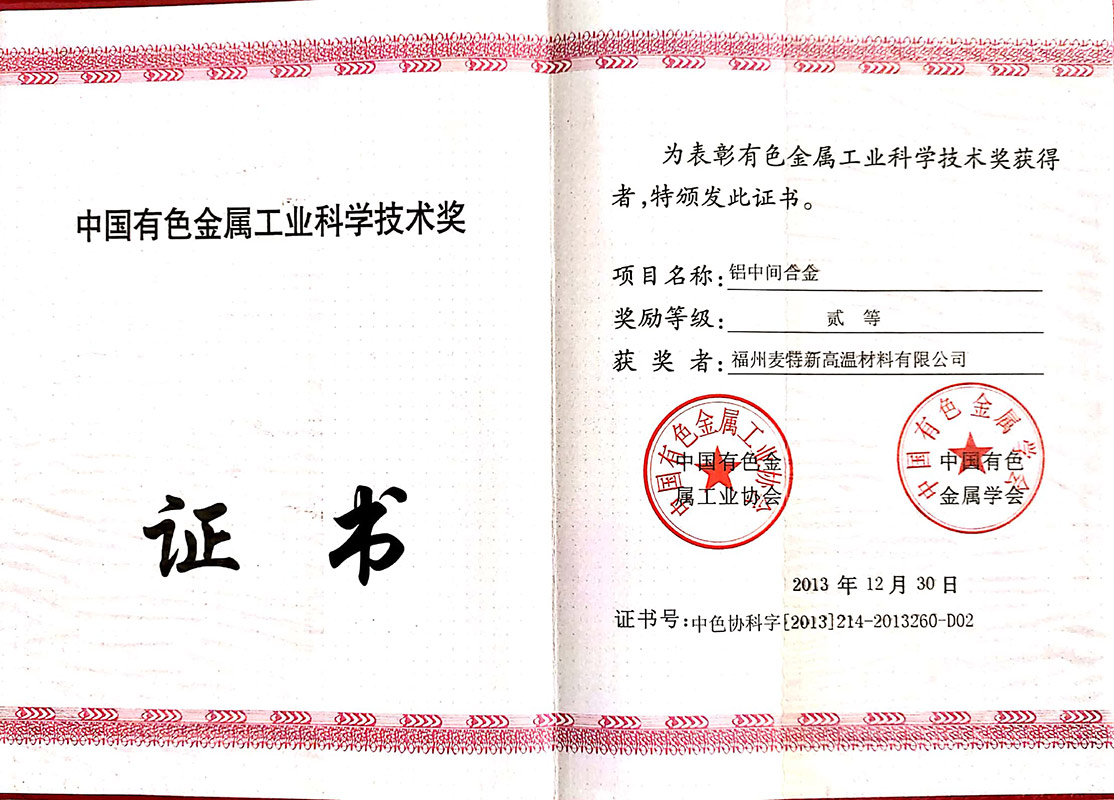

Second Prize of the Science and Technology Award for China's Nonferrous Metals Industry in 2013

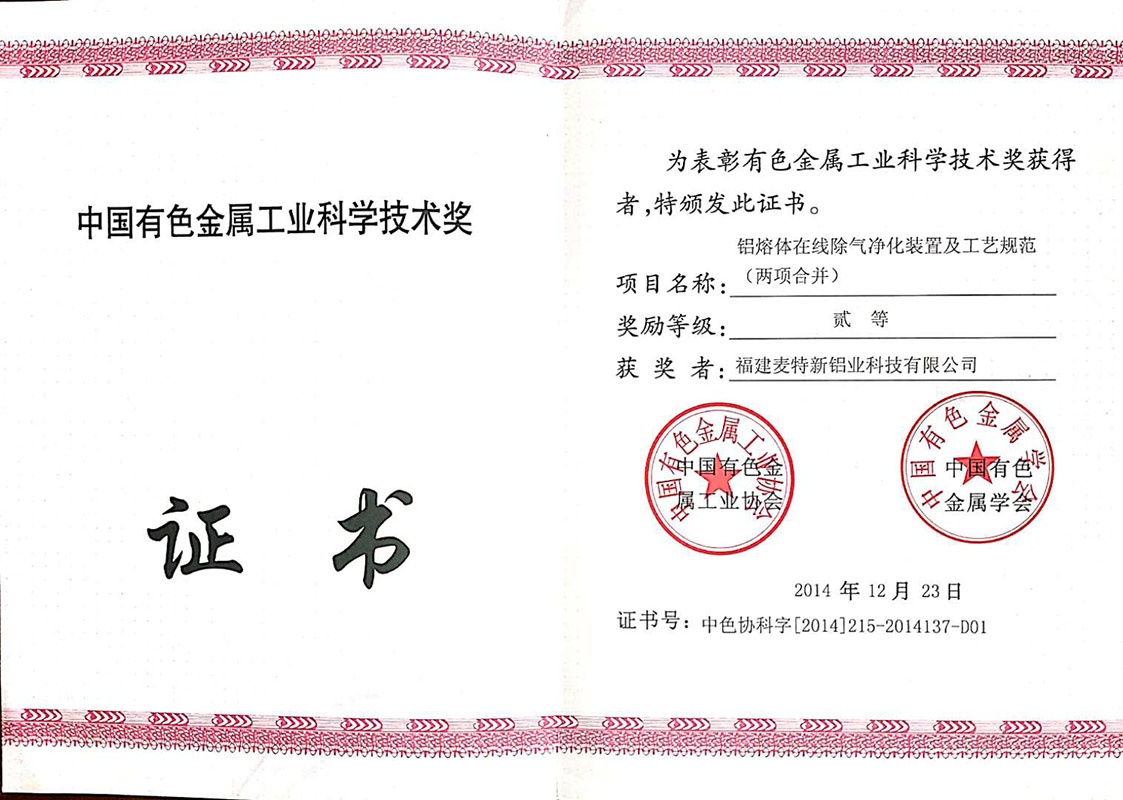

Second Prize of the Science and Technology Award for China's Non ferrous Metals Industry in 2014

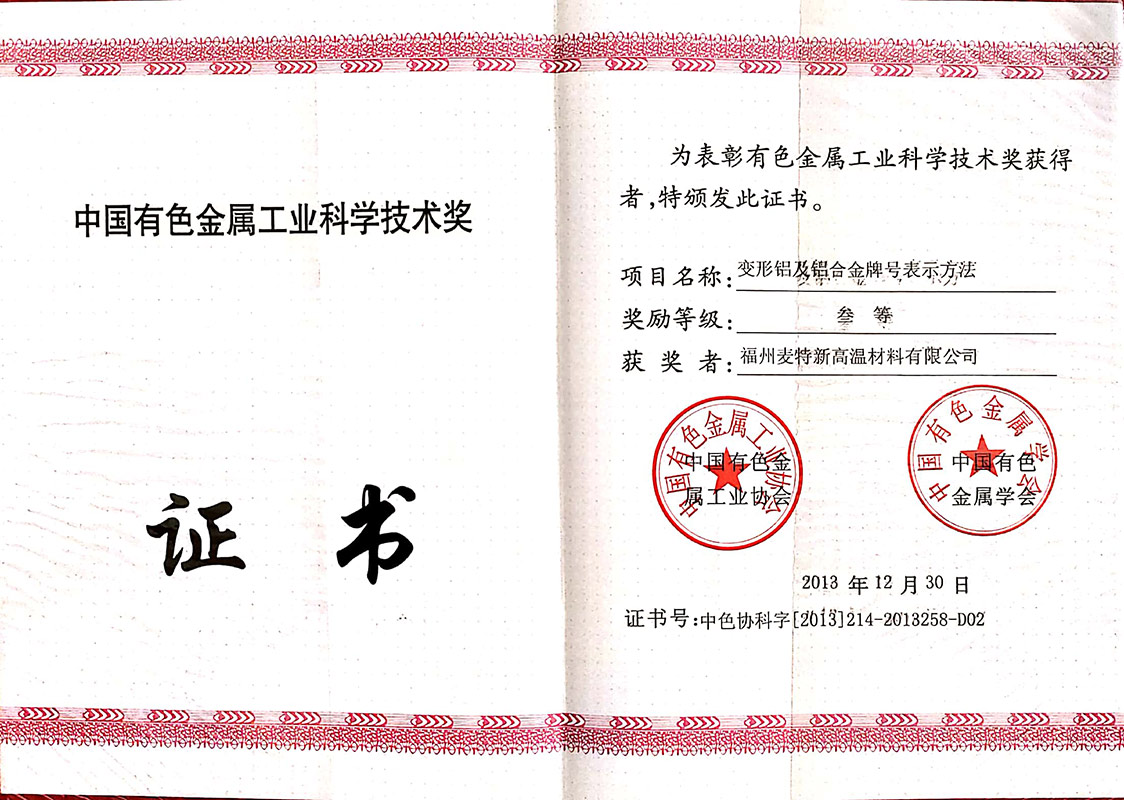

Third Prize of China Non ferrous Metals Industry Science and Technology Award in 2013

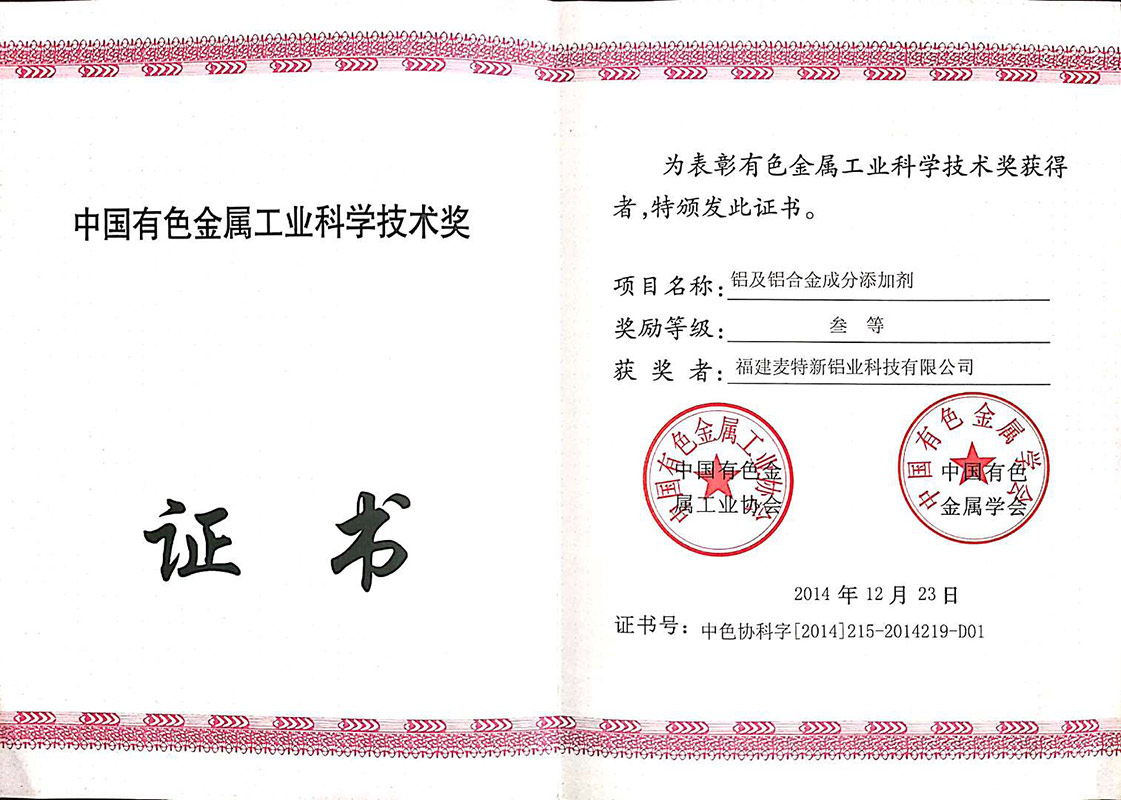

Third Prize of the 2014 China Nonferrous Metals Industry Science and Technology Award

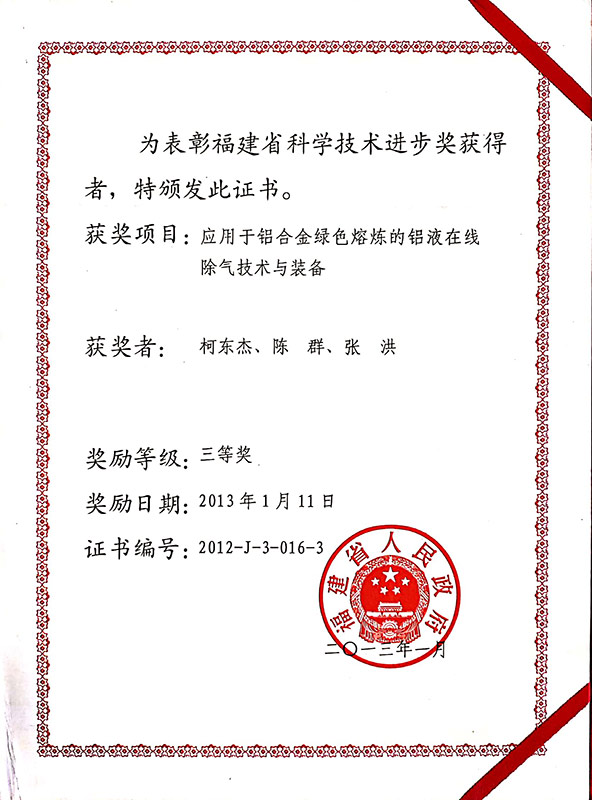

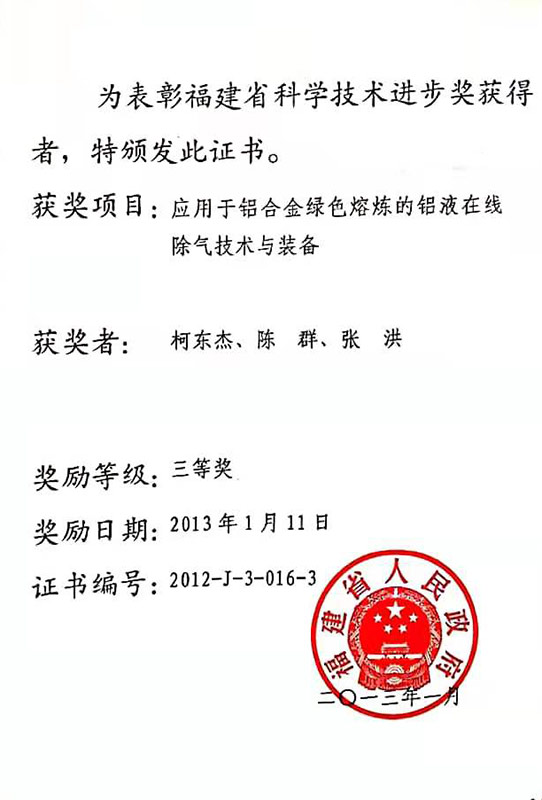

Third Prize of Fujian Provincial Science and Technology Progress Award in 2013

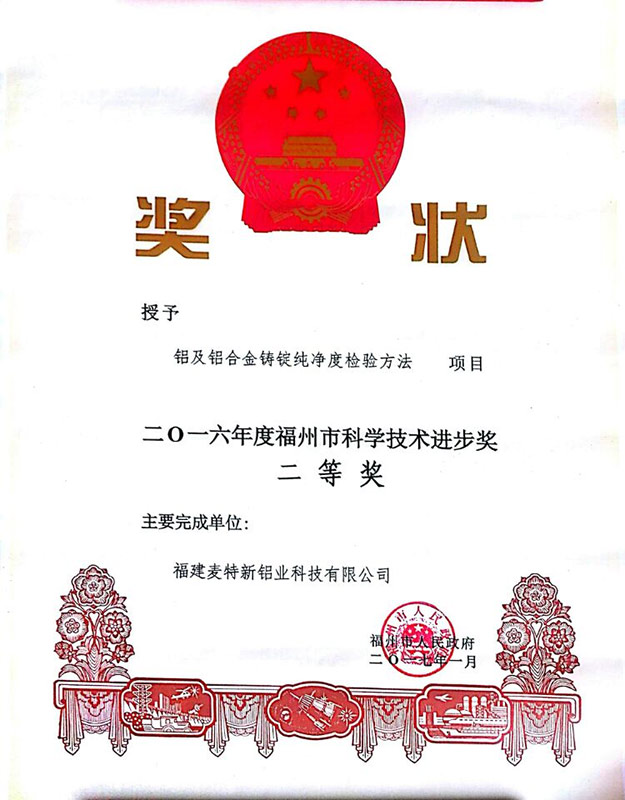

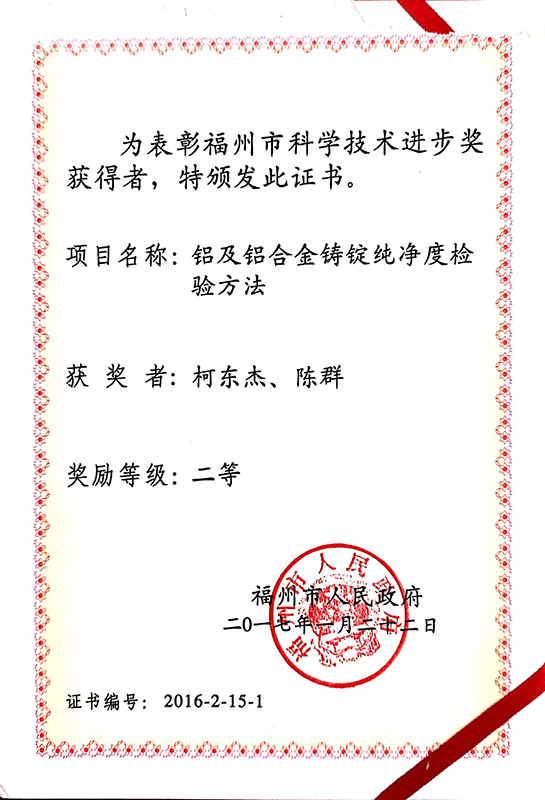

The second prize of Fuzhou Science and Technology Progress Award in 2016

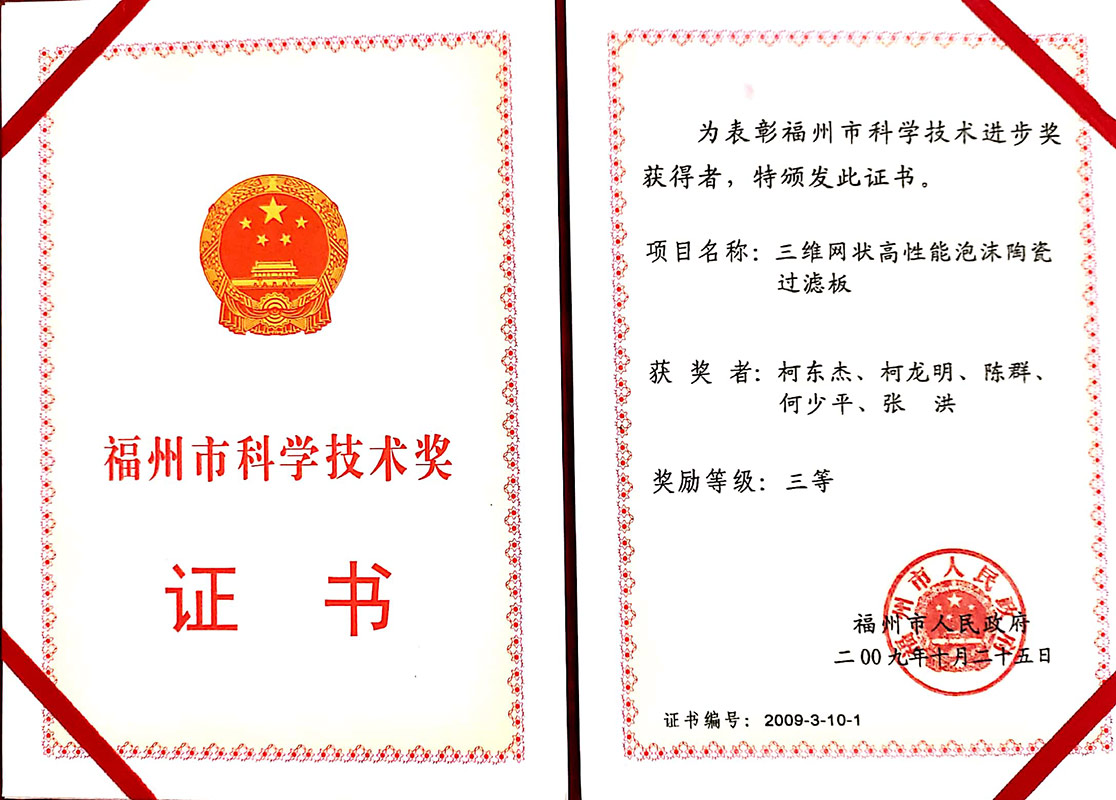

The third prize of Fuzhou Science and Technology Progress Award in 2009

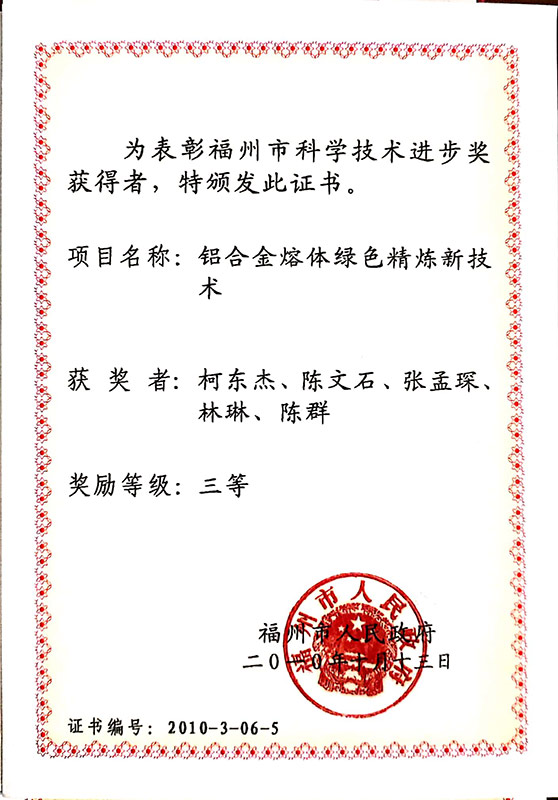

The third prize of Fuzhou Science and Technology Progress Award in 2010

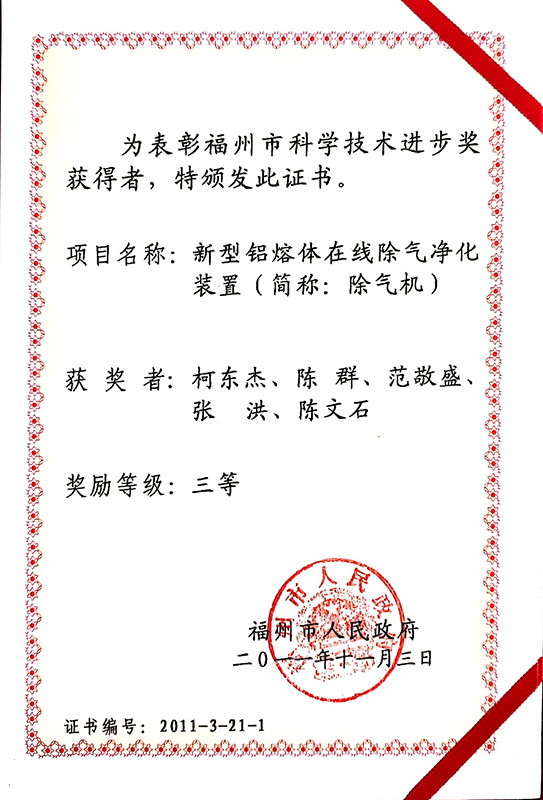

In 2011, the third prize of Fuzhou Science and Technology Progress Award won 5 invention patents and 9 utility model patents. The invention patents are as follows:

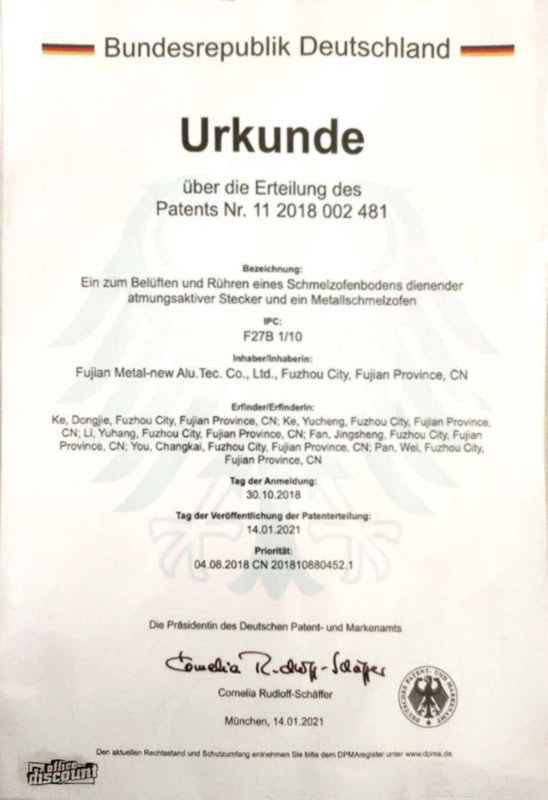

A breathable plug for ventilation and stirring at the bottom of a smelting furnace and a metal smelting furnace ZL201810880452.1;

A metal smelting method and smelting furnace ZL201810557056.5;

Ein zum Bel ü ften und R ü hren eines Schmelzofenbodens diender atmungsaktivir Stecker und einMetallschmelzofen (German invention patent) 112018002481.4;

A high-precision aluminum alloy thin-walled seamless tube extrusion method ZL201911384436.4 for the nuclear industry; A green method for removing alkali metals from aluminum and aluminum melt ZL202110626364.0.

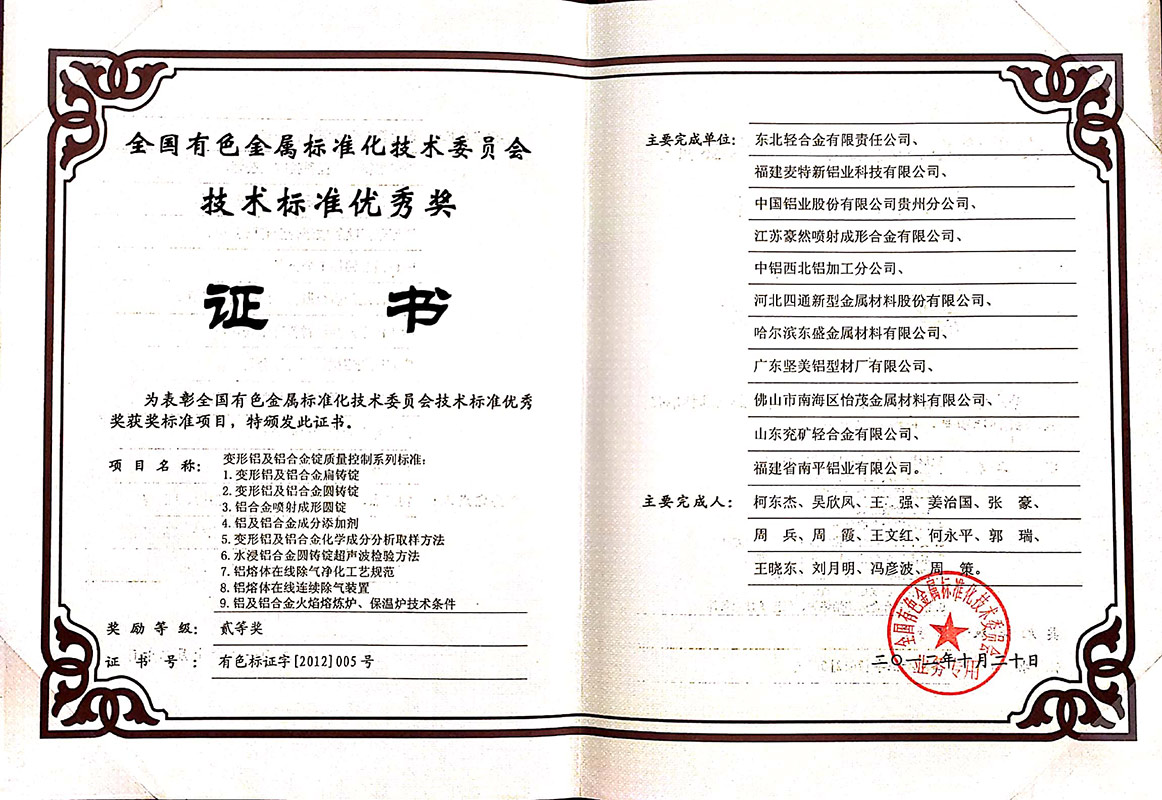

Formerly edited and formulated six national and industry standards:

National standards: "Aluminum Intermediate Alloy", "Method for Indicating Wrought Aluminum and Aluminum Alloy Grades", "Inspection Method for Purity of Aluminum and Aluminum Alloy Ingots" Industry standards: "Online Continuous Degassing Device for Aluminum Melt", "Specification for Aluminum Alloy Online Degassing and Purification Process", "Additives for Aluminum and Aluminum Alloy Composition"

Compiled and published two monographs: "Theory and Process of Aluminum Alloy Melting" and "Contemporary Aluminum Melt Treatment Technology", becoming the first monograph on aluminum melt treatment technology in the non-ferrous metal industry since the 60th anniversary of the founding of the People's Republic of China